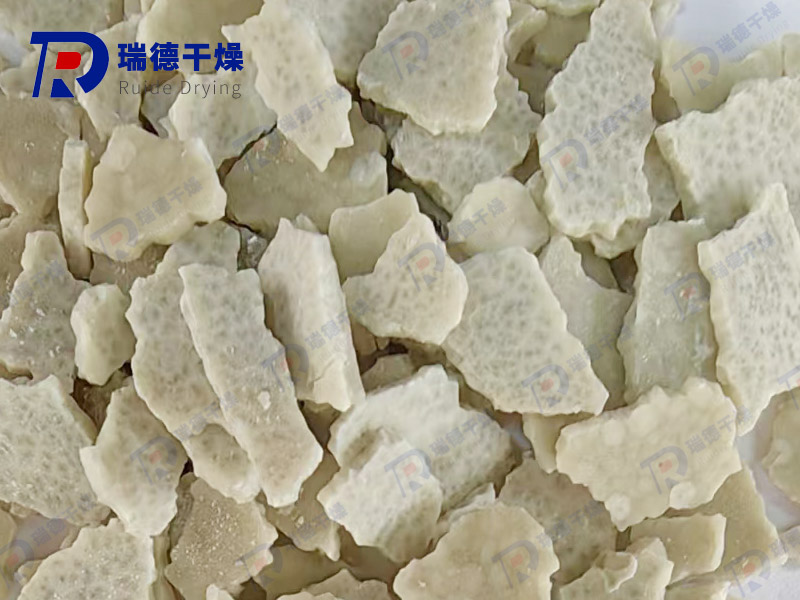

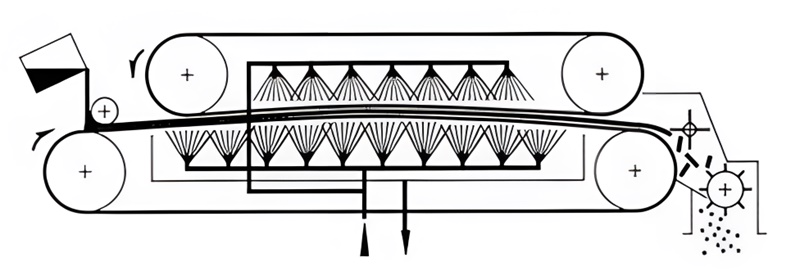

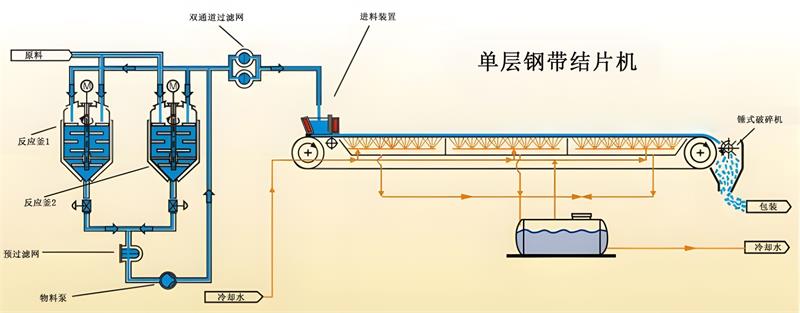

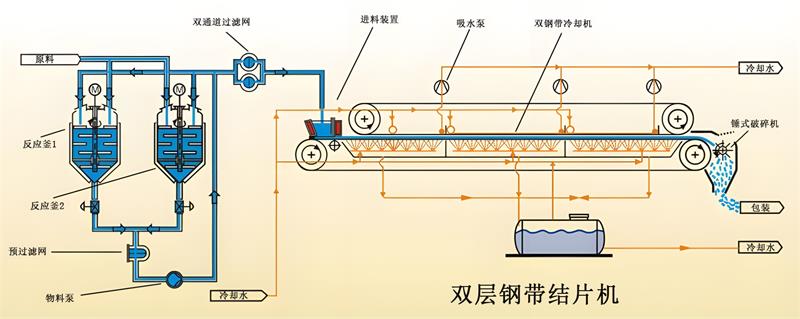

The RDJP series steel strip laminating machine is divided into single-layer and double-layer. The steel strip laminating machine utilizes the characteristic that the melting point of the material is below 300 ℃. According to the viscosity range of the material in the molten state, a special fabric device is used to evenly distribute the molten liquid on the steel strip that moves uniformly below it. Under the cooling effect of the continuous spray device set below the steel strip, the material is cooled, solidified, crushed, and packaged during transportation, thus achieving the purpose of laminating.

This product is a new type of (melting) forming and laminating machine. The work changes from liquid to solid through transportation and cooling, and materials with a melting point range of 50 ℃ to 300 ℃ can be formed into flakes. No dust, improved production environment; And it has certain economic value (energy-saving, packaging container economy), fast product replacement, uniform production of sheet products, adjustable thickness, and no thermal stress; Sliced products are easy to package, transport, store, and also convenient for users to measure, mix, or remelt, enabling continuous production. From feeding to packaging, it reduces physical labor, has stepless speed regulation, adjustable flow rate, and easy operation. Widely used in industries such as petroleum and fine chemicals. One machine can be used for making strips, pieces, and sheets; Toxic materials can be sealed in a lump.

◆ Quick curing reduces contact time with air and prevents material discoloration.High output, shortened production cycle

◆ Less dust, improve production environment.

◆ The product is uniform and conducive to terminal measurement.

◆ Reasonable and compact structure, easy maintenance, capable of continuous operation and improving production efficiency.

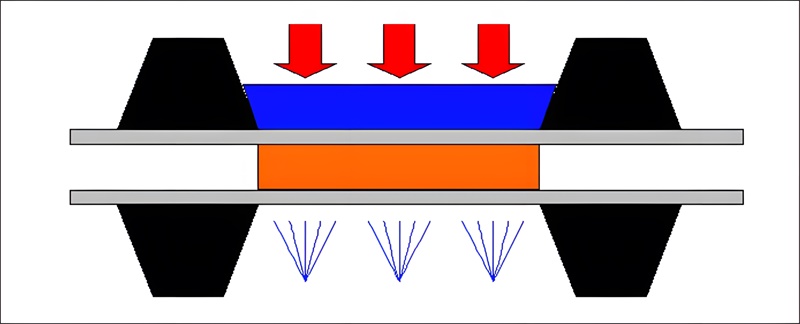

The liquid material flows through the mixing and heating pipeline into the fabric device (overflow groove) at the front end of the equipment, and continuously overflows from the overflow groove, evenly distributed between the two layers of moving steel strips without interruption. The material is uniformly cooled by cooling water between the upper and lower layers of steel strips, and the excellent heat transfer characteristics of the steel strips themselves are used to solidify the liquid material into solid material sheets during the movement process. The cured product is scraped off from the steel strip by a cutting scraper, then crushed by a crusher, collected, and directly enters the packaging process. The laminating machine will adopt PLC centralized control, with multiple protection functions such as speed, liquid level, motor thermal protection, upstream and downstream interlocking, and a high degree of automation. Dangerous and vulnerable areas are equipped with safety protection devices, electrical safety interlock switches or emergency stop devices, and have good safety performance. In the laminating machine, the cooling water does not come into direct contact with the material, and the product will neither be contaminated nor change its composition. Cooling water can be recycled or directly discharged without pollution, and will not cause any pollution to the environment.

Such materials include petroleum resin, rosin and rosin resin, epoxy resin, polyamide resin, polyester resin, C5 resin, C9 resin, C5C9 polymer resin, phenolic resin, paraffin wax, sulfur, asphalt, asphalt, aluminum sulfate, hot melt sol, stearate, carved block, maleic anhydride, p-nitrochlorobenzene, anti-aging agent, fatty acid, partial anhydride, calcium chloride, meta phenylenediamine, catechol, sodium hydrosulfide, refined p-dichlorobenzene, partial anhydride, stearic acid, sulfurized alkali, urea, rubber additive, various additives, plastic additives, antioxidants, anti-aging agents, stabilizers, mold inhibitors, fungicides, etc.

Resin industry, polyester resin, epoxy resin, rosin resin, ink resin, phenolic resin, etc.

Previous:Sulfur Flaking Machine

Next:none!