In a dispersion where solid powder and liquid coexist and the solid phase is the main component, the self adhesiveness of the dispersion (or the addition of a binder) is utilized to force the basic particles of the solid powder to adhere and increase in size through methods such as compression, gravity, centrifugal force, mechanical force, and airflow impact. And form a uniform and concentrated particle group with a certain shape and particle size. The complete set of wet granulation equipment mainly consists of mixing (kneading), granulation, drying and its auxiliary system equipment. After mixing (kneading) the powder, it enters the granulator to form a wet product with the required particle size, and is dried to obtain a granular finished product, thus achieving the purpose of granulation.

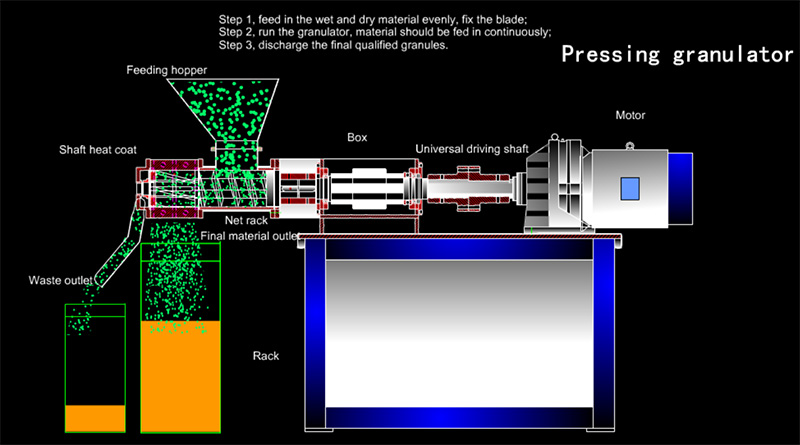

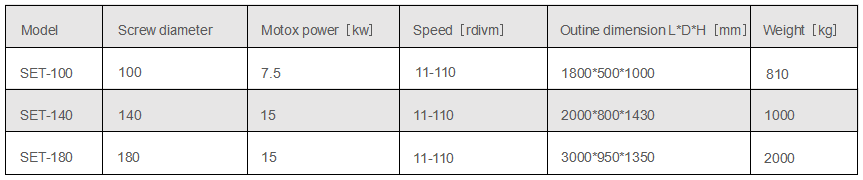

The SET type twin-screw extruder granulator is divided into front discharge type and side discharge type. The diameter of the front discharge type granulator is generally selected between 1.5-12mm, and the diameter of the side discharge type granulator is generally selected between 0.7-2.0. The particle shape is cylindrical, and the granulation rate is ≥ 95%. The discharge port is equipped with a particle cutting device, and the long strip naturally forms particles after drying. The front end of the equipment is also equipped with a water cooling device to reduce the temperature inside the pipe and speed up the discharge.

Widely applicable to products that require granulation in industries such as rubber additives, food additives, plastic additives, powdered activated carbon, catalysts, feed, pesticides, dyes, pigments, daily chemicals, pharmaceuticals, etc.

This machine is suitable for wet production of various specifications of granules in industries such as pharmaceuticals, chemicals, food, and feed. The particles produced by this machine are hard extruded through screws and mesh plates, so the particle shape is regular, the texture is tight, the powder is small, and it is not easy to absorb moisture. The product has a long shelf life and is particularly suitable for making granular granules and other products in the pharmaceutical and instrument industries. The parts of this machine that come into contact with materials are made of stainless steel, making surface polishing, assembly, disassembly, and cleaning very convenient.