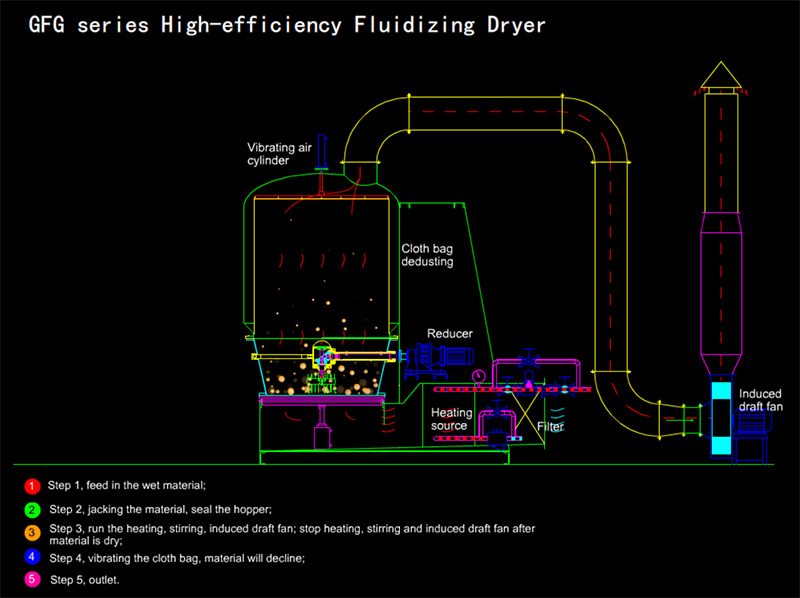

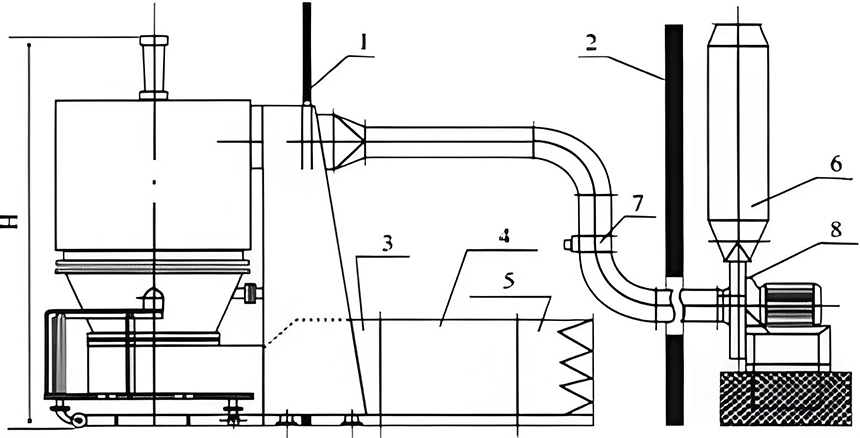

The GFG series boiling dryer is a new type of boiling drying equipment developed for GMP pharmaceutical engineering. The equipment consists of an air filter, heater, main unit, material cart, ash cleaning chamber, connecting air duct, fan, muffler, etc. It can be used in conjunction with a swing granulator or wet granulator, and has a wider fluidization range than the traditional XF series horizontal fluidized bed. Widely used in the fields of medicine, chemical industry, food, feed, etc., for drying wet granules and powdered materials.

Under the action of the high-pressure centrifugal fan, the air is filtered through the air filter, heated to the set temperature in the air heat exchanger, and then formed through the gas distribution plate to impact the material, the negative pressure formed between the gas bundle material, so that it becomes boiling. In this state, the hot air is in extensive contact with the material, which enhances the heat transfer process, and thus promotes the evaporation and separation of water in the material in a short time. The wet air is discharged by the fan through the collection bag, and the material trapped in the boiler by the collection bag is dry product.

1. Mechanical screw extrusion granules, swinging granules, wet high-speed mixed granulation granules< br/>2、 Drying of wet granules and powdered materials in the fields of medicine, food, feed, chemical engineering, etc< br/>3、 Large particles, small pieces, sticky block granular materials< br/>4、 Materials such as konjac and polyacrylamide that undergo volume changes during drying.

1. The fluidized bed has a circular structure to avoid dead corners.

2. The hopper is set with mixing to avoid the aggregation of wet materials and the formation of channel flow during drying.

3. Adopting the method of tipping and dumping materials, it is convenient, fast, and thorough, and an automatic feeding and discharging system can also be designed according to requirements.

4. The equipment has a wider fluidization range and can handle particles that are too wet, sticky, or have a wide particle size distribution, resulting in significant drying effects.

5. The drying speed is fast, the temperature is uniform, and the drying time for each batch is generally 20-30 minutes.

6. Sealed negative pressure operation, the gas is filtered and has good sealing performance. The entire equipment is easy to operate, disassemble, and clean, and meets the requirements of "GMP".

1. Preparation stage: Adjust the compressed air to 0.35~0.4Mpa, check the rotation of the fan, and its operation is carried out according to the corresponding instructions.

2, operation: Put the material to be dried into the hopper, and then put the skip into the corresponding position of the main engine.

3. The "jacking" cylinder seals the upper and lower flanges of the hopper.

4. Set the air inlet temperature for drying to the required value.

5, start the induced draft fan - start the mixing motor.

6, after the material is dry, turn off the motor - stop the induced draft fan - manual ash cleaning several times - "top drop" hopper - discharge.