The SZG double cone vacuum dryer is a new generation drying device developed by our factory in combination with similar domestic product technology. The double cone vacuum adopts a belt chain elastic connection method, so the equipment runs smoothly. The specially designed process fully reflects the good concentricity of the two shafts, and reliable mechanical seals or American technology rotary joints are used for both the heat medium and vacuum system. On this basis, we have developed SZG-A, which can achieve both stepless speed regulation and constant temperature control.

As a drying equipment manufacturer, our products range from high temperature heat transfer oil to heat medium, medium temperature steam and low temperature hot water.

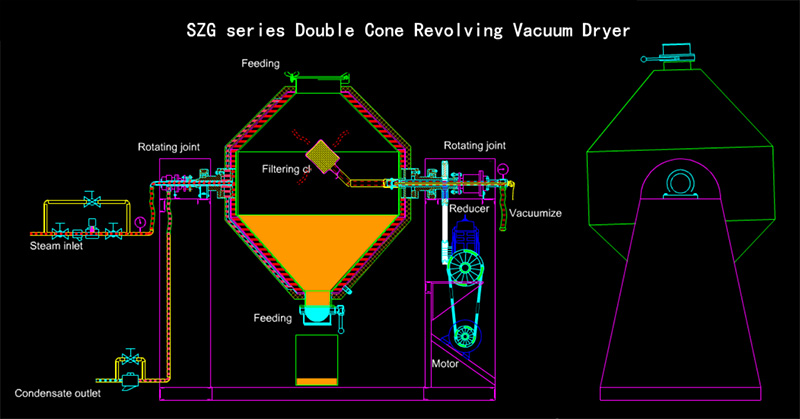

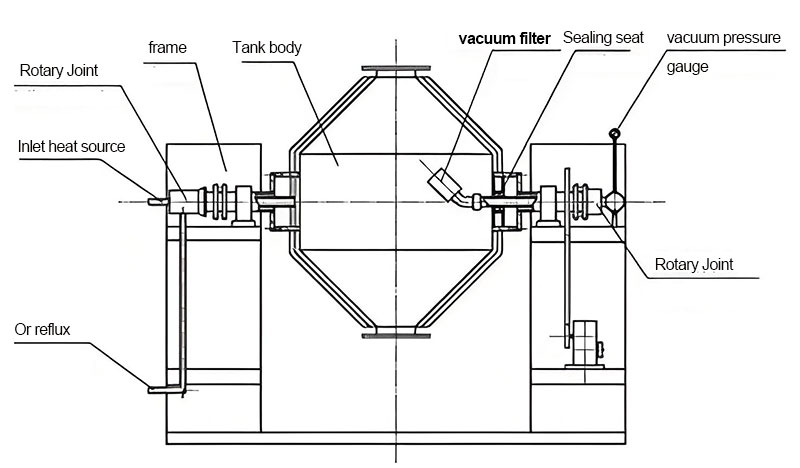

◎ Heat energy (such as hot water, low pressure steam or heat conduction oil) is passed into the closed interlayer, and the heat is transferred to the material to be dried through the inner shell.

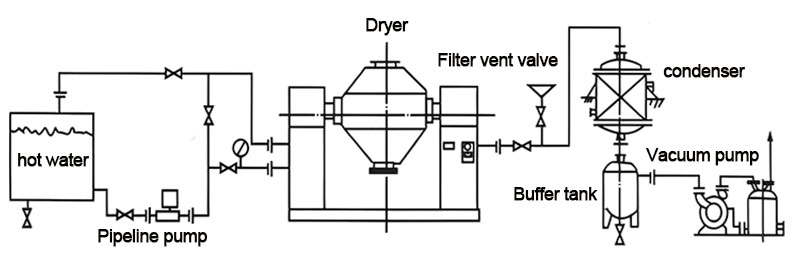

◎ Under the power drive, the tank is rotated slowly, and the materials in the tank are continuously turned over, so as to achieve the purpose of strengthening the drying. ◎ The material is in a vacuum state, the vapor pressure drops so that the water (solvent) on the surface of the material reaches a saturated state and evaporates, and is discharged and recycled by the vacuum pump in time. The water (solvent) inside the material continuously penetrates to the surface, evaporates and drains, and the material achieves the purpose of drying in a short time.

Suitable for the concentration, mixing, drying of powders, granules, and fibers in industries such as chemical, pharmaceutical, and food, as well as materials that require low-temperature drying (such as biochemical products). More suitable for drying materials that are easily oxidized, volatile, heat sensitive, strongly irritating, toxic, and materials that do not allow crystal destruction.

◎ When oil is heated. Adopt automatic constant temperature control. Can dry biochemical products

◎ and mineral raw materials, the temperature can be between 20 ~ 160oC. High thermal efficiency, more than 2 times higher than the general oven.

◎ Indirect heating Material will not be contaminated, in accordance with "GMP" requirements. Equipment maintenance operation is simple, easy to clean.

◎ Suitable for solvent recovery process.

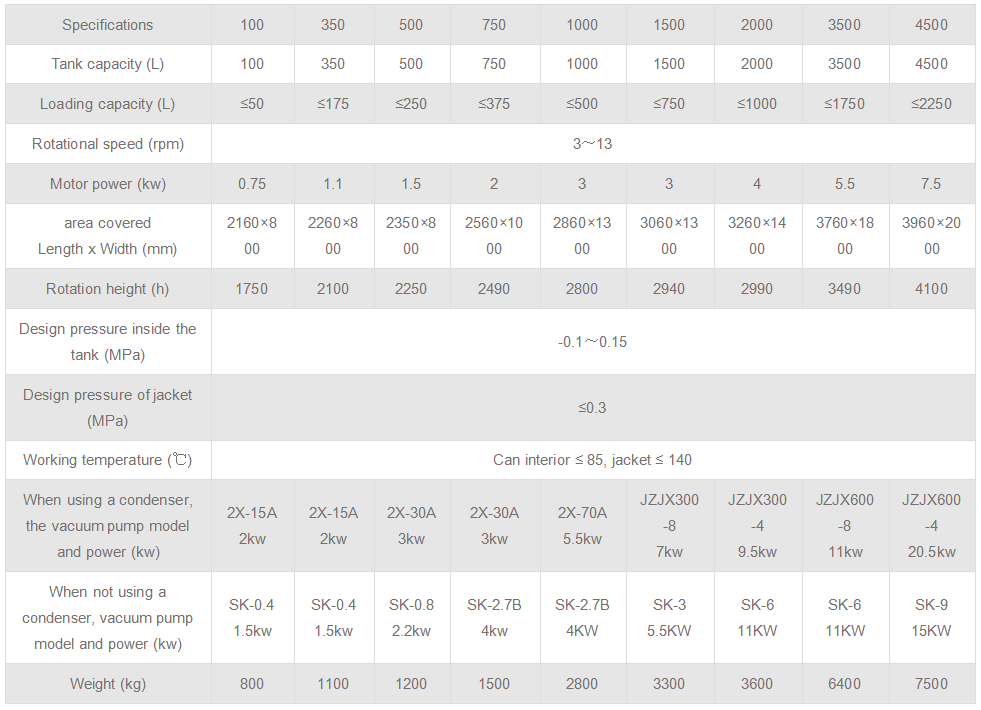

Note: For materials with significant volume changes before and after drying, the loading coefficient can be appropriately increased or decreased, and the maximum loading volume should not come into contact with the bottom of the vacuum tube. The motor can be equipped with a speed control motor according to user requirements, with a speed range of 0-6r.p.m; The above technical parameters are calculated based on a material specific gravity of 0.6g/cm3. If it exceeds this value, it must be raised when placing an order; If the user needs a pressure vessel certificate, they need to request it when placing an order; If the inner liner material is made of enamel glass, it needs to be specified when placing an order; If the material is flammable and explosive, it must be clearly stated when ordering, otherwise its use is strictly prohibited.

Ordering Notice:

1, heating is divided into hot water, heat conduction oil heating two forms.

2, when ordering, please indicate the temperature that the material can withstand or the temperature of the dryer, so that the factory can choose or provide heat sources for you.

3. When drying sticky materials, the factory will specially design the "sheet" structure in the tank.

4, the accessories involved in the vacuum drying system, our factory can provide and install for users, please specify in the order.

5, the factory can provide design, manufacturing and installation for the special requirements of users.